Rigid Boxes: A Cost-Effective Packaging Option

When it comes to the packaging industry, you’re probably familiar with the common options such as cardboard boxes and paper bags. But have you ever heard of custom rigid boxes? Rigid packaging boxes are a cost-effective and stylish packaging option that is quickly gaining popularity in the market. In this blog post, we discuss the basics of rigid boxes, how they can benefit your business, and why they are a great choice for any packaging project. Read on to learn more about this innovative packaging solution and how it might be able to help your business stand out from the competition.

What are Rigid Boxes?

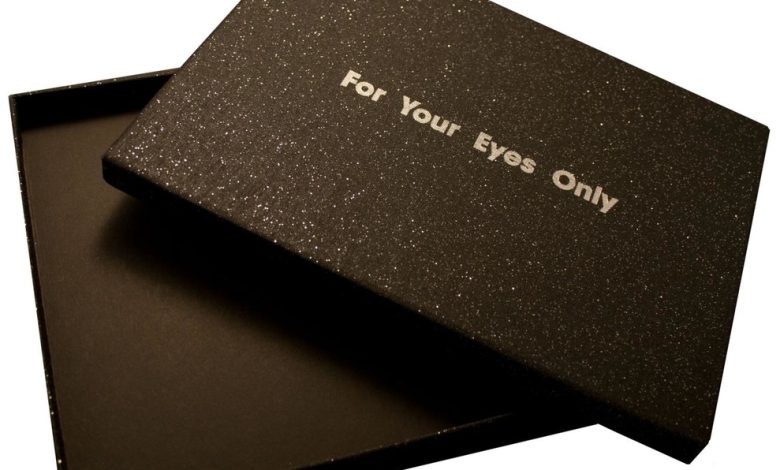

Rigid boxes are a type of packaging that is typically made from cardboard or paperboard. These boxes are designed to be strong and durable, making them an ideal option for packaging products that need to be protected from damage during shipping and handling. Rigid packaging boxes can also be customized to meet the specific needs of your product, which makes them a versatile packaging option for a variety of products.

The Benefits of Rigid Boxes

There are many benefits to using rigid boxes for packaging. They are a cost-effective option that can save you money on shipping and packaging costs. Rigid shipping boxes are also very durable and can protect your products from damage during shipping and storage. Additionally, custom rigid boxes are easy to assemble and can be customized to fit your specific product needs.

The Cost of Rigid Boxes

Rigid boxes are a great option for packaging because they are cost-effective and offer a lot of protection for your product. However, there are some costs associated with custom rigid packaging that you should be aware of before you make your final decision. The cost of the materials for a rigid box will vary depending on the size and style of the box. The material for the box itself is usually cardboard, but you may also need to purchase foam or other padding to protect your product inside the box. The more complicated the design of the box, the more expensive it will be. You will also need to factor in the cost of shipping when you are calculating the cost of rigid boxes. Rigid packaging boxes are larger and heavier than other types of packaging, so they will cost more to ship. If you are shipping internationally, you should expect to pay even more for shipping costs. When you are considering the cost of custom rigid boxes, be sure to compare it with other packaging options. Rigid boxes may be more expensive up front, but they offer a lot of value in terms of protection and durability.

How to Find the Right Rigid Box Supplier

There are a few key factors to consider when choosing a rigid box supplier. The first is experience. Make sure the supplier has experience in manufacturing rigid packaging. The second is capability. Ask the supplier if they have the ability to meet your volume requirements. The third is cost. Get quotes from several suppliers to compare prices. The fourth is lead time. Make sure the supplier can meet your deadlines. The best way to find a qualified rigid box supplier is to ask for referrals from other businesses in your industry. Another option is to search online for suppliers that specialize in manufacturing rigid shipping boxes

How to Design a Custom Rigid Box

If you are looking for a way to package your product in a unique and attention-getting way, consider using a custom rigid box. Custom rigid packaging are made from sturdy cardboard that is printed with your design. They can be customized to any size or shape, and can be printed with your company logo or other marketing materials. Here are some tips for designing a custom rigid box: 1. Consider the size and shape of your product. You will need to choose a box that is large enough to fit your product, but not so large that it seems empty. If you have a larger product, you may want to consider using a two-piece box so that it can be shipped flat and assembled by the customer. 2. Choose a thick cardboard material. This will ensure that your box is strong and durable, and will protect your product during shipping. 3. Select a printing method that will make your design pop. Offset printing is a popular option for rigid shipping boxes because it produces high-quality results. However, digital printing is also an option if you want to save money on printing costs.

https://www.supremecustomboxes.com/rigid-boxes/ 4. Decide how you want to finish your box. A matte finish will give your box a sophisticated look, while a gloss finish will make your colors really stand out. You can also choose to add special effects like embossing or foil stamping to make your box even more eye-catching

Conclusion

Rigid boxes are an excellent, cost-effective packaging option for many businesses. They are strong and durable, which makes them perfect for protecting goods during transit or storage. They also provide a great canvas for customization with endless design possibilities to make your product stand out on the shelves. With all of these benefits in mind, it’s clear why rigid packaging have become so popular among businesses looking to save money while still delivering quality packaging solutions.