The heart of any timepiece, its intricate movement, is a marvel of micro-engineering. Yet, its ability to function accurately and reliably depends critically on how it is housed. The process of fitting this delicate engine into its protective case is far from simple; it is governed by exacting standards of precision that separate a truly fine watch from a mediocre one. At the center of this process is the case ring, or movement holder, an often-overlooked component that plays a pivotal role in the watch’s longevity and performance. Understanding the precision required for this fit reveals a deeper appreciation for the art and science of horology.

The Unsung Hero: The Case Ring

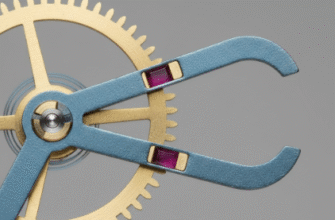

Before diving into the specifics of tolerances, it’s essential to understand what the case ring does. This component, typically made from metal like brass or steel in higher-end watches and a durable polymer in more accessible ones, serves several crucial functions. Its primary job is to secure the movement within the watch case, preventing it from shifting or rattling. This isn’t just about preventing an annoying noise; it’s about protecting the movement from shock and ensuring perfect alignment with other critical parts of the watch.

The case ring ensures that the winding stem lines up precisely with the movement’s keyless works and the crown tube on the case. A slight misalignment here could make winding gritty, difficult, or even lead to a broken stem. It also properly positions the dial relative to the case and the crystal, ensuring the hands have adequate clearance to rotate without fouling on each other or the crystal’s underside. Essentially, it is the skeleton that holds everything in its correct and intended position.

Materials and Design Philosophy

The choice of material for a case ring often reflects the watch’s overall quality and price point. A machined metal ring, often specific to one particular case and movement combination, offers the ultimate in rigidity and precision. It provides a solid, unyielding connection that is ideal for absorbing and dissipating shock. In contrast, polymer rings offer excellent shock absorption due to their inherent elasticity and have the manufacturing advantage of being able to accommodate slight variations in case or movement dimensions, making them ideal for mass production.

A common misconception is that plastic case rings are inherently inferior. While metal is preferred in luxury watchmaking for its precision and durability, modern high-grade polymers are incredibly stable, resistant to shock, and do not corrode. For many watches, a well-engineered polymer holder provides superior shock protection compared to a poorly fitted metal one. The quality of the fit is ultimately more important than the material itself.

The Science of Fit: Tolerances and Clearances

The world of watchmaking operates on a microscopic scale. When we talk about a “perfect fit” for a movement, we are discussing tolerances measured in hundredths of a millimeter, or microns. For context, a human hair is about 70 microns thick. The acceptable gap, or play, between the movement, case ring, and case is often significantly smaller than that. This precision is broken down into two main axes: radial and axial play.

Radial Play: The Side-to-Side Fit

Radial play refers to the movement’s potential to shift from side to side within the case. The ideal is not zero play, but an extremely controlled, minimal amount of clearance. If the fit is too tight, temperature fluctuations can cause the case and movement to expand at different rates, inducing stress on the movement’s plate and bridges. If it’s too loose, the entire movement and dial assembly can shift during a shock or even from the normal motion of the wearer’s wrist.

A typical high-quality standard for radial clearance between the movement and the case ring might be between

0.02mm and 0.05mm. This tiny gap is just enough to allow for assembly and thermal expansion without allowing any perceptible movement. A loose fit can lead to several problems:

- Winding Stem Damage: As the movement shifts, it puts lateral pressure on the winding stem, which can cause it to bend or break over time.

- Dial Misalignment: The dial, attached to the movement, can shift off-center relative to the case aperture, creating an unsightly aesthetic flaw.

- Reduced Shock Resistance: While it seems counterintuitive, a slight amount of play can cause more damage. A loose movement can accelerate and build momentum before striking the inside of the case, amplifying the G-force of an impact.

It is absolutely critical that the dial feet, which secure the dial to the movement, and the casing screws, which secure the movement to the case ring, are properly tightened. Even with perfect component tolerances, a loose screw can negate the entire precision assembly. This is a common point of failure in poorly serviced or assembled watches. The integrity of the fit relies on every component working in unison.

Axial Play: The Up-and-Down Fit

Axial play concerns the vertical movement within the case, between the dial and the case back. Like radial play, the goal is a precisely controlled, minimal clearance. If the fit is too loose (too much axial play), the movement can shift up and down. This can cause the hands to touch the underside of the crystal or, conversely, for the automatic winding rotor to scrape against the inside of the case back. Both scenarios can cause damage and stop the watch.

If the fit is too tight, constant pressure is exerted on the movement from the case back. This pressure can be transferred through the movement’s bridges to the delicate pivots of the gear train or balance wheel, creating friction and negatively impacting the watch’s accuracy and amplitude. The standard for axial clearance is often even tighter than for radial play, sometimes as low as

0.01mm to 0.03mm. This is achieved through the precise height of the case ring and the design of the case back, which often has a specific profile to apply just the right amount of pressure via the gasket without touching the movement itself.

Achieving Unseen Precision

These incredibly tight tolerances are not achieved by accident. They are the result of advanced manufacturing and meticulous quality control. Computer Numerical Control (CNC) machines can mill watch cases and metal movement rings to micron-level accuracy. During assembly, watchmakers use digital calipers, depth micrometers, and custom gauges to verify every dimension. For a watch to receive a prestigious certification like the Geneva Seal, the quality of the casing and the fit of the movement holder are scrutinized just as closely as the decoration on the movement’s bridges. It is a testament to the idea that in watchmaking, every single detail, seen or unseen, contributes to the final quality of the timepiece.