The allure of an automatic watch lies in a seemingly magical concept: a mechanical device that powers itself, seemingly forever, with no batteries required. This elegant autonomy is not magic, but a triumph of micro-engineering, and at its very heart is a component known as the

rotor. While often beautifully decorated and visible through an exhibition case back, the rotor is far more than an aesthetic flourish. It is the engine’s flywheel, the primary energy harvester that transforms the simple, everyday movements of the wearer into the potential energy that brings the watch to life. Understanding its function is to understand the very soul of automatic timekeeping.

The Kinetic Converter: What is a Rotor?

At its most basic, a rotor, or oscillating weight, is a weighted, semi-circular piece of metal mounted on a central pivot. This pivot allows it to swing freely within the watch case. When you move your arm, gravity and inertia act upon this weight, causing it to rotate. This rotation, however, is not without purpose. Through a series of intricate gears and clutches collectively known as the winding train, the rotor’s rotational energy is harnessed and used to wind the mainspring. The mainspring is a tightly coiled ribbon of metal that, when wound, stores potential energy. It is this stored energy that is slowly released through the escapement to power the watch’s hands.

Think of it like a water wheel in a gentle stream. The subtle currents of your daily motion are the water, and the rotor is the wheel. Each small movement nudges the rotor, causing it to turn. This turning action engages the gearing system, which methodically tightens the mainspring, ensuring a continuous supply of power. The design genius lies in converting chaotic, multi-directional human movements into a controlled, singular-purpose action: winding.

The Science of the Swing: Mass, Inertia, and Energy

The efficiency of a rotor is deeply rooted in fundamental physics. The goal is to generate the maximum amount of winding force from the minimum amount of wrist motion. This is governed by the principles of

kinetic energy and

moment of inertia. The formula for kinetic energy is KE=21mv2, where m is mass and v is velocity. This simple equation reveals why the material of a rotor is so critical.

To maximize the energy captured, watchmakers must maximize the mass (m) of the rotor. This is why rotors are rarely made from steel like the rest of the movement. Instead, they are crafted from much denser metals.

Tungsten is a popular choice in modern watchmaking due to its exceptional density and relative cost-effectiveness. In high-end, luxury timepieces, you will often find rotors made from

22k or 24k gold, and sometimes even

platinum. These precious metals are not just for show; their superior density allows a smaller or thinner rotor to possess the same mass as a larger tungsten one, providing crucial clearance within the tight confines of a watch case while still delivering powerful winding action.

Furthermore, it’s not just about total mass, but where that mass is distributed. By concentrating the weight along the outer curved edge of the semi-circle, engineers increase the rotor’s

moment of inertia. This makes it more susceptible to initial movement and allows it to build and maintain momentum more effectively, swinging with greater force even from a gentle nudge. This is why rotors are not solid discs; the semi-circular shape is a deliberate engineering choice to optimize this physical property.

A well-designed automatic winding system is remarkably effective. For an individual with a moderately active lifestyle, wearing the watch for just 8 to 10 hours can be sufficient to fully wind the mainspring. This provides a power reserve that can often last between 38 and 70 hours, depending on the specific watch movement. This efficiency is a direct result of optimizing rotor mass and the mechanics of the winding train.

Directional Dynamics: The Winding Mechanism

A spinning rotor is useless if its energy isn’t properly channeled. The true ingenuity of automatic systems is found in the mechanism that connects the rotor to the mainspring barrel. This mechanism must convert the rotor’s potentially chaotic, back-and-forth spinning into a unidirectional winding of the spring. There are two primary schools of thought on how to achieve this: unidirectional and bidirectional winding.

Unidirectional Winding

In a unidirectional system, the rotor only winds the mainspring when it rotates in one specific direction (either clockwise or counter-clockwise). When it spins in the opposite direction, it freewheels without engaging the winding gears. The primary advantage of this system is its mechanical simplicity and lower friction in the disengaged direction, which can lead to a very free and fast-spinning rotor, often referred to as the “wobble”. While less efficient in theory, as it discards half of the potential movements, a vigorous rotor spin in the “dead” direction can build enough momentum to complete several full rotations, with the final one often being in the “live” winding direction, thus still capturing some energy.

Bidirectional Winding

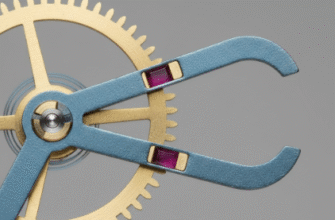

Considered a more advanced and efficient solution,

bidirectional winding incorporates a special mechanism, often called a reverser switch or a system of click wheels. This clever assembly of gears automatically reverses the direction of the winding action when the rotor changes its spin. This means that regardless of whether the rotor swings left or right, it is always actively winding the mainspring. The famous Pellaton winding system developed by IWC is a classic example, using an ingenious pawl-and-cam system to achieve this. Rolex’s Perpetual rotor system is another benchmark for quiet and effective bidirectional winding. The benefit is clear: every bit of kinetic energy, from every motion, is captured and put to use. This makes the watch wind faster and more reliably, especially on the wrists of less active wearers.

The debate between the two systems continues among horologists. While bidirectional is technically more efficient at capturing energy, the unidirectional systems, with their lower component count and friction, can be incredibly robust and effective in their own right. The choice often comes down to a manufacturer’s heritage and engineering philosophy.

The Pivot Point: Bearings and Longevity

The rotor is one of the most active components in a watch, potentially completing thousands of rotations every day. The point where it connects to the movement must therefore be incredibly durable and low-friction. Early automatic watches often used a simple jeweled staff or pivot. While effective, this single point of contact could be a vulnerability to shocks and wear over time. A hard knock could damage the pivot, and years of constant rotation could introduce friction, hampering winding efficiency.

To solve this, most modern automatic movements mount the rotor on a set of miniature

ball bearings. This system distributes the load and shock across multiple points, making it vastly more robust and shock-resistant. The ceramic or steel balls provide a smooth, low-friction surface for the rotor to spin on, ensuring that the slightest motion is translated into rotation with minimal energy loss. This small, often-overlooked detail is crucial for the long-term reliability and efficiency of the entire automatic winding system, ensuring the rotor can perform its essential role for decades.