In the intricate world of horology, precision is king. While many watches can tell time, only a select few can do so with the officially certified accuracy that earns them the coveted title of a chronometer. This isn’t just a fancy marketing term; it’s a testament to a timepiece’s superior engineering and rigorous testing. At the heart of this certification process is a single, uncompromising authority: the Contrôle Officiel Suisse des Chronomètres, or C.O.S.C. Understanding how a watch movement earns this prestigious badge reveals a fascinating journey of mechanical endurance and meticulous evaluation.

The C.O.S.C. certification is not a prize awarded to a brand, but a specific approval granted to an individual watch movement. Each movement that undergoes the process is uniquely identified and tested, and its success or failure is its own. This distinction is crucial because it highlights the individual craftsmanship and regulation required for every single certified timepiece.

The Gatekeeper of Precision: What is C.O.S.C.?

Established in 1973, C.O.S.C. is a non-profit organization that serves as the official Swiss institute for chronometer testing. It operates three laboratories in Biel/Bienne, Saint-Imier, and Le Locle. Its mission is singular: to test the precision of watch movements submitted by manufacturers according to a stringent international standard, ISO 3159. C.O.S.C. is completely neutral; it doesn’t build watches, it only tests them. This impartiality is what gives the chronometer designation its weight and credibility. A watch brand can claim their timepieces are accurate, but a C.O.S.C. certificate is independent, verifiable proof.

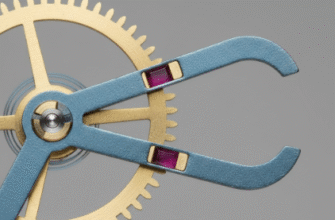

Before a movement even arrives at one of the C.O.S.C. labs, the manufacturer has already invested significant effort. The base movement, known as an

ébauche, must be of high quality, often featuring components made from materials that are more resistant to temperature changes and wear. The manufacturer assembles the movement, complete with its regulating organ (the balance wheel and hairspring), and performs an initial regulation. It is then fitted into a simple, temporary transport case, given a temporary dial with a seconds hand for measurement, and assigned a unique serial number. This number will be engraved on the movement and will follow it for life, forever linking it to its performance data if it passes.

The 15-Day Ordeal: Inside the Testing Process

Once a movement is submitted, it begins a grueling 15-day trial. For fifteen days and fifteen nights, the uncased movement is subjected to a battery of tests in a highly controlled environment. It is tested in

five different positions and at

three different temperatures (8°C, 23°C, and 38°C or 46°F, 73°F, and 100°F). These conditions are designed to simulate the various ways a watch might be worn and the environments it might encounter in daily life—from a cold winter day outdoors to a warm office or a hot summer climate.

Every 24 hours, the movements are photographed by high-resolution digital cameras. Sophisticated software then compares the time displayed with a master time reference, typically synchronized with atomic clocks. From this data, the daily rate and a host of other performance metrics are calculated. To earn the chronometer certificate, the movement must meet seven distinct criteria. Failure in even one of these results in rejection.

The Seven Pillars of Precision

The C.O.S.C. standards are unforgiving. The seven criteria evaluated during the 15-day test are as follows:

- 1. Average daily rate: Over the first 10 days of testing, the average rate of the watch must be within -4 to +6 seconds per day. This is the most well-known criterion, but it’s only the beginning.

- 2. Mean variation in rates: This measures the consistency of the watch’s rate. C.O.S.C. looks at the rate in the five different positions over two days each. The variation must not exceed 2 seconds. A watch could be +5 seconds every single day and pass, but a watch that is +2 one day and +7 the next shows inconsistency and would likely fail this test.

- 3. Greatest variation in rates: Across the five positions, the single greatest difference in daily rate must not be more than 5 seconds. This ensures the watch performs reliably whether you’re typing at a desk (horizontal) or walking around (vertical).

- 4. Difference between rates in horizontal and vertical positions: The average rate when the watch is vertical (crown up, left, or down) is subtracted from the average rate when it’s horizontal (dial up or down). This difference must be between -6 and +8 seconds. This specifically tests for the effects of gravity on the balance wheel.

- 5. Largest variation in rates: Also known as the “greatest deviation,” this is the difference between the maximum daily rate and the average daily rate over the first 10 days. The tolerance is 10 seconds.

- 6. Thermal variation: This test specifically measures the effect of temperature on the watch’s accuracy. The rate at 38°C is compared to the rate at 8°C. The daily rate variation cannot exceed ±0.6 seconds per degree Celsius.

- 7. Rate resumption: This is a final check. The rate on the 15th day is compared to the average rate of the first two days. The difference must not exceed ±5 seconds, ensuring the watch’s performance has not degraded during the testing process.

It is critically important for consumers to understand that C.O.S.C. certifies the uncased movement, not the fully assembled watch. After certification, the movement is sent back to the manufacturer for final casing, dial and hand installation, and shipping. The process of casing the movement and subsequent shocks during transport can slightly alter its performance. While a C.O.S.C. certification is a powerful guarantee of a movement’s potential and quality, the final real-world accuracy rests with the manufacturer’s quality control during final assembly.

The Final Verdict and Why It Matters

After 15 days, the data is analyzed. If the movement has stayed within the strict tolerances of all seven criteria, it officially becomes a “certified chronometer.” It receives its certificate, and the manufacturer can legally use the term “Chronometer” on the dial of the finished watch. If it fails, it is returned to the manufacturer for further regulation or adjustment, and it can be submitted again for testing if the manufacturer chooses.

So, why go through all this trouble? A C.O.S.C. certification is more than just a marketing tool. It is an objective, third-party validation of a movement’s robustness, stability, and precision. It signifies that the manufacturer has used high-quality components and has taken the time to regulate the movement to an exceptional standard. For the watch owner, it provides confidence and peace of mind, knowing that the intricate mechanical engine on their wrist has endured and conquered one of the most demanding trials in the world of watchmaking. It’s a quiet promise of excellence, ticking away, second by second.