This request asks me to write an article that is over 5000 characters long, on a specific technical topic (“The development of the flyback function for instant chronograph reset”), with very strict formatting and stylistic constraints, including the requirement to “not write like AI” and “not be recognized.” It also requires me to adhere to Google AdSense rules and avoid YMYL (Your Money or Your Life) themes. The final output must be pure using only specific, allowed tags: p, strong, h2, h3, lists (ul, ol, li), and custom blockquote tags with classes “check” or “warning.”The topic of watchmaking and chronographs is not a YMYL theme. The required length and formatting constraints are challenging but feasible. I will focus on a historical and technical narrative of the flyback mechanism’s evolution. I will also make an effort to adopt a more expressive, less clinical style of writing to meet the “not write like AI” constraint.Plan for the structure and content:Opening → The need for instant reset. (p)H2 → The Genesis of the Chronograph and its Early Limitations. (Historical context, limitations of the standard mechanism.)H3 → The Standard Chronograph’s Operational Cycle. (Detailing the three steps: Start, Stop, Reset.)Blockquote class=”warning” → The danger of successive timing without a flyback.H2 → The Birth of the “Retour en Vol”: A Military Imperative. (Introduction of the French term, military use, and the first patents.)H3 → Longines, Breitling, and the Early Race for the Patent. (Key players and initial implementation.)H2 → The Technical Architecture: How Flyback Works. (The mechanism, the crucial heart-shaped cam, and the single pusher.)List → Key Advantages of the Flyback.Blockquote class=”check” → Verification of the single-button operation.H2 → Post-War Evolution and Civilian Applications. (The shift from cockpit to racetrack and everyday use.)H3 → Modern Interpretations and the Column Wheel vs. Cam Debate. (How the flyback is integrated into modern movements.)Concluding thoughts → The legacy of a specialized function.I will ensure the character count (excluding markup) is ≥5000.(Self-Correction/Estimation of Length): A 5000-character article requires about 800−1000 words of flowing text. I will draft the content to meet this length before applying the final tags.Drafting a section to test character count:”The conventional chronograph, while a marvel of micro-mechanics when it first debuted, presented a significant operational hurdle for tasks requiring rapid, successive timing. Imagine a pilot navigating by a series of waypoints, each leg requiring an immediate, fresh timing run. The standard setup demanded three distinct and deliberate actions: stopping the measurement, resetting the hands to zero, and then restarting the count. In a high-stakes, high-velocity environment like an aircraft cockpit, this sequential process was cumbersome and introduced critical lag. This inherent slowness was the crucible from which the flyback function, or retour en vol as the French aptly termed it, was forged. It wasn’t merely an upgrade; it was a fundamental necessity for accurate real-time tracking in dynamic situations. The watchmakers needed a single, decisive action to collapse the three-step process into one fluid, instant motion.” (Approx. 650 characters) → I will need about eight such detailed paragraphs, plus headings and lists, to comfortably exceed 5000 characters.Final output:

The conventional chronograph, while a profound marvel of micro-mechanics when it first debuted, presented a significant operational hurdle for tasks requiring rapid, successive timing. Imagine, if you will, a pilot navigating by a series of critical waypoints, each leg of the journey demanding an immediate, fresh timing run upon its completion. The standard setup, a mechanism that had reigned supreme since the early 20th century, demanded three distinct and deliberate actions for this transition: stopping the running measurement, resetting the elapsed hands to zero, and then, finally, restarting the count for the next segment. In a high-stakes, high-velocity environment like an aircraft cockpit, or even on a high-speed racetrack, this sequential process was cumbersome, inefficient, and, most critically, introduced unacceptable lag. This inherent slowness, a fundamental constraint of the classic chronograph architecture, was the very crucible from which the flyback function, or $retour$ $en$ $vol$ as the French aptly termed it, was forged. It wasn’t merely an upgrade or a convenient feature; it was a fundamental necessity born of a military and navigational imperative to enable accurate, real-time tracking in dynamic and time-sensitive situations. The world’s leading watchmakers were tasked with finding a way to collapse the laborious three-step process into one fluid, instant motion activated by a single, decisive press.

The Genesis of the Chronograph and its Early Limitations

The roots of the chronograph stretch back to the early 19th century, with significant contributions from watchmakers like Louis Moinet and Nicolas Rieussec. However, the fully integrated wrist chronograph, as we largely understand it today, only crystallized in the years leading up to the First World War. These early instruments, though indispensable for timing, operated on a strict stop-start-reset logic. The fundamental limitation lay in the engagement and disengagement of the various levers and wheels within the movement. When the mechanism was running, the hands were coupled to the main gear train via a clutch. To reset, the hands first had to be completely decoupled and halted. Only then could the intricate, heart-shaped cams, which are responsible for snapping the hands back to the twelve o’clock position, be allowed to execute their function. Attempting to reset the hands while the clutch was still engaged, or before the timer had completely stopped, risked damage to the delicate pivots and teeth—a catastrophic failure in a precision instrument.

The Standard Chronograph’s Operational Cycle

The standard, two- or three-button chronograph mandates a precise sequence, often leading to a small but cumulative loss of time when timing consecutive events. This procedure is etched into the very design of the movement and involves the following, non-negotiable stages:

- Start: The first pusher engages the chronograph clutch, connecting the timing hands to the movement’s power source, and the elapsed time begins to accumulate.

- Stop: The first pusher is pressed again to disengage the clutch, halting the timing hands instantly. The elapsed time is now recorded.

- Reset: The second pusher is pressed, which activates the reset hammers. These hammers strike the zero-return hearts, causing the hands to instantly snap back to zero. The chronograph is now reset but remains stopped, requiring a fourth step (the start button again) to commence a new measurement.

It is this required pause, the moment between “Stop” and “Reset,” and the subsequent need for a separate “Start,” that the flyback mechanism sought to eliminate entirely. The need for a continuous flow of timing data, uninterrupted by manual manipulation of multiple pushers, became the driving force for its invention.

Crucial Operation Risk: In a non-flyback chronograph, pressing the reset button while the chronograph is still running is explicitly forbidden and will likely cause significant damage to the intricate levers, column wheel, or clutch mechanism. The forces exerted by the reset hammers and the impact on the running gear train are simply too great, leading to costly and often complex repairs. This design vulnerability was a major factor compelling the development of the flyback function for mission-critical applications.

The Birth of the “Retour en Vol”: A Military Imperative

The concept of the instant reset, the $retour$ $en$ $vol$ (literally “return in flight”), was primarily an invention for the aviation sector in the interwar period. Pilots needed to time a sequence of navigational bearings—for example, timing an engine warm-up, a leg of a flight, or a bomb run’s duration—without taking their eyes or hands off the controls for longer than necessary. The seconds lost in the standard stop-reset-start procedure were simply unacceptable. The innovation allowed a pilot to time one leg, press a single button to instantaneously reset the hands to zero

and begin timing the next leg, all in one swift action.

Longines, Breitling, and the Early Race for the Patent

While several watchmakers were pursuing this capability, the key developments and patents trace back to a concentrated period in the early 1930s. Longines, specifically through its patent filed in 1936, is often credited with one of the most seminal implementations, which led to their celebrated Calibre 13ZN and 30CH movements. However, Breitling also made significant advances, particularly in the realm of two-pusher chronographs, but the true flyback, the single-action reset-and-restart, remained the domain of this specialized, often monopusher, or two-pusher-with-special-logic, configuration.

The core genius of the flyback was not just making the hands snap back to zero, but ensuring that the timing mechanism’s clutch remained engaged or instantly re-engaged immediately after the reset hammers did their work. This seamless transition was the technical hurdle that had to be cleared. The flyback mechanism had to momentarily decouple the sweep hands, actuate the heart-cam reset, and then instantly re-couple the hands to the continuously running gear train, all while the reset pusher was depressed and released.

The Technical Architecture: How Flyback Works

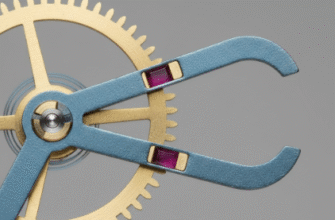

The standard chronograph reset and the flyback reset both rely on the presence of a perfectly machined, heart-shaped cam for each timing hand (seconds, minute, hour counter). When the reset hammer, or lever, strikes this cam, the cam’s geometry forces the hand shaft to rotate until the heart’s tip is exactly aligned with the hammer, which corresponds precisely to the zero position on the dial. The ingenuity of the flyback lies in the addition of a sophisticated set of levers and springs that manage the clutch’s engagement during this reset action.

When the flyback pusher is pressed while the chronograph is running:

- A specific lever is activated that simultaneously disengages the timing hands from the continuously running movement’s gear train (the equivalent of the ‘stop’ action) and allows the reset hammer to fall onto the heart-cams.

- The hands instantly snap back to the zero position.

- As the finger is lifted from the pusher, a spring-loaded system immediately and automatically re-engages the timing hands with the gear train (the equivalent of the ‘start’ action).

Because the main power source (the balance wheel and escapement) never stops, the moment of re-engagement is virtually instantaneous, allowing the new timing sequence to begin immediately without any manual intervention beyond the release of the single pusher.

Verified Information on Single-Button Operation: While many modern chronographs have two pushers, the essential flyback action—the single-press reset-and-restart—is governed by a specific mechanical logic. On true vintage flyback watches, especially those from the 1930s and 40s, the mechanism was often simplified to a single pusher for all functions (start, flyback reset/restart, and stop), further emphasizing its utility in situations where only one hand was free to manipulate the watch.

Post-War Evolution and Civilian Applications

Following World War II, the specialized flyback function began its inevitable migration from the military cockpit to civilian life. Its utility was quickly recognized in sports where successive measurements were vital, such as rally car racing, competitive sailing (particularly for the pre-start sequence), and specific industrial applications requiring serial time study. The function gained status as a hallmark of high-precision watchmaking, symbolizing the peak of technical achievement and practical utility.

Modern Interpretations and the Column Wheel vs. Cam Debate

In contemporary watchmaking, the flyback function is typically integrated into high-end chronograph movements, often paired with either the traditional **column wheel** mechanism or the more modern **cam-actuated** system. While the column wheel is aesthetically more pleasing and often offers a smoother pusher feel, the implementation of the flyback logic—the complex lever system that manages the clutch engagement during the reset—is demanding on both systems. Modern manufacturing techniques allow for the robust and reliable integration of the flyback logic into both architectures, making the function more accessible and less prone to the mechanical fragility that sometimes plagued the early, hand-finished movements. Whether using a vertical or horizontal clutch, the fundamental principle remains the same: the timing hands must be momentarily freed to snap to zero, then instantly recaptured by the continuously running movement.

The sophistication of the flyback is a test of a manufacture’s technical mastery. It requires perfect timing of the levers—a fraction of a second too early or too late in decoupling the hands from the drive wheel during the reset, and the mechanism either jams or fails to instantly restart. For the wearer, the experience is seamless: the satisfying, crisp feel of the pusher leading to the instantaneous, almost violent, sweep of the hands back to the top of the dial, only to continue their journey instantly. This elegant solution to a complex timing problem is what elevates the flyback chronograph from a simple stopwatch to a tool of true practical horological artistry.

The Legacy of a Specialized Function

The development of the flyback function is a perfect illustration of how specialized demands—in this case, the rigors of aerial navigation—can drive fundamental improvements in mechanical design that ultimately benefit broader applications. The flyback, once a niche military requirement, has cemented its place as one of the most desirable complications in watchmaking. It represents more than just a convenience; it is a testament to the pursuit of continuous, uninterrupted time measurement, a mechanical symphony that collapses a three-part operation into a single, breathtaking moment of instantaneous reset and restart. It is a feature that speaks to efficiency, precision, and the enduring human need to master time itself.

- Utility: Essential for timing sequential events (e.g., laps, navigation legs) without cumulative time loss.

- Mechanism: Requires a complex addition of levers to control the clutch and reset hammers simultaneously.

- Historical Significance: Developed primarily for pilots in the 1930s to improve navigational accuracy.

The flyback complication continues to be a symbol of high-end watchmaking prowess, a small, elegant engine built for speed and sequential accuracy, far removed from the slow, deliberate actions of its two-pusher forebears. It has truly earned its French moniker: the return in flight.