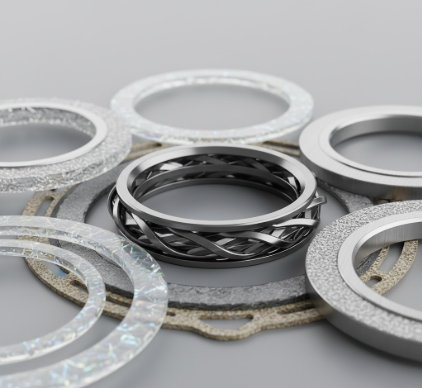

Gaskets and seals are the unsung heroes of the mechanical world. From the engine in your car to the pipes in your home, these humble components perform the critical task of preventing leaks. They create a barrier between two surfaces, ensuring fluids and gases stay where they’re supposed to. For decades, the effectiveness of these seals was limited by the materials available. However, a quiet revolution in material science has transformed these simple parts into highly engineered components, enabling technology to become more powerful, efficient, and reliable. This journey from leaky leather washers to advanced synthetic polymers is a testament to human ingenuity.

From Cork and Leather to Synthetic Rubber

In the early days of the industrial revolution, engineers had a limited palette of materials for sealing. They relied on natural substances like cork, felt, leather, and asbestos. While functional for the low-pressure, low-temperature applications of the time, they had significant drawbacks. Cork would dry out and crack, leather required constant lubrication, and natural rubber would quickly degrade when exposed to oil, sunlight, or extreme temperatures. A car engine from the 1920s, for example, would leak oil by design simply because the gasket materials couldn’t withstand the heat and chemical exposure for long. The need for something better was clear.

The breakthrough came with the advent of synthetic polymers. Chemists began to create materials in the lab that could outperform their natural counterparts in almost every way. This was the true beginning of modern sealing technology.

The Rise of All-Purpose Synthetics

One of the first game-changers was

Neoprene (polychloroprene), introduced in the 1930s. It offered a balanced profile of properties, boasting moderate resistance to oils and chemicals, but its real advantage was its superior resistance to environmental factors like ozone, UV light, and weathering. Suddenly, seals used in outdoor applications or exposed to the elements had a much longer lifespan.

Shortly after,

Nitrile rubber (NBR) emerged as the go-to material for oil and fuel applications. Its molecular structure makes it exceptionally resistant to petroleum-based fluids. This made it an instant star in the automotive and industrial worlds. Gaskets for fuel pumps, oil pans, and hydraulic systems could now be made from NBR, drastically reducing leaks and improving reliability. For any application involving oils, greases, or hydrocarbon fuels, nitrile became the standard choice for decades.

Silicone rubber stands out for its incredible thermal stability. Standard grades can typically handle continuous operating temperatures from -60°C up to 230°C (-76°F to 446°F). This broad temperature range makes it indispensable in applications that experience extreme heat and cold, such as automotive engine seals and aerospace components.

Pushing the Temperature Boundaries

While Neoprene and Nitrile solved many problems, they still struggled with extreme temperatures. This is where

Silicone rubber (VMQ) made its mark. Silicone boasts an incredibly wide operating temperature range, remaining flexible at frigid lows and stable at scorching highs where other rubbers would become brittle or melt. This property made it perfect for applications like oven door seals, engine gaskets in specific high-heat zones, and seals used in aerospace where temperature fluctuations are extreme. While not as tough or abrasion-resistant as Nitrile, its thermal stability and excellent resistance to weathering and ozone carved out a critical niche.

As technology progressed, so did the demands placed on seals. Jet engines, aggressive chemical processing, and high-performance automotive systems created environments that were too harsh for even the best synthetic rubbers. The challenge was no longer just about handling oil or moderate heat; it was about withstanding a cocktail of corrosive chemicals at extreme temperatures and pressures. This need spurred the development of an elite class of materials: fluoropolymers.

The Ultimate Chemical and Heat Resistance: FKM

Fluoroelastomers, most famously known by the DuPont trade name Viton® (FKM), represented a quantum leap in performance. By incorporating fluorine into the polymer backbone, chemists created a material with outstanding resistance to a vast range of chemicals, fuels, acids, and oils, all while operating at very high temperatures (often exceeding 200°C). FKM became essential for critical applications where failure was not an option. You’ll find FKM O-rings and seals in aircraft fuel systems, chemical processing plants, and high-performance automotive engines. Its development enabled engineers to design systems that operated under conditions previously thought impossible.

The Slipperiest Material: PTFE

Another member of the fluoropolymer family,

Polytetrafluoroethylene (PTFE), is known to most people as Teflon®. While not an elastomer (it’s a rigid plastic), its properties revolutionized sealing, particularly in dynamic applications. PTFE has one of the lowest coefficients of friction of any solid material, meaning it’s incredibly slippery. This makes it ideal for seals that have to move, such as piston rings, bearing seals, and valve stem seals, where it reduces wear and operating effort. Furthermore, PTFE is almost completely chemically inert, able to withstand even the most corrosive acids and solvents. Often, PTFE is used as a filler in other elastomers or as a cap on an O-ring to combine its low-friction and chemical-resistant properties with the flexibility of rubber.

Modern Innovations: Smart Materials and Design

The evolution didn’t stop with high-performance polymers. The latest advancements focus on fine-tuning materials and integrating them with intelligent design. Material scientists now act like master chefs, creating custom recipes by adding fillers to base polymers. Adding

carbon black can increase strength and abrasion resistance,

silica can enhance tear strength, and

graphite can be used to reduce friction or dissipate static electricity. This allows for the creation of gasket materials tailored to very specific operational demands.

Another significant advancement is the move towards

liquid and form-in-place (FIP) gaskets. Instead of stamping out a gasket from a sheet of material, a robotic arm applies a bead of liquid sealant (often a Room-Temperature Vulcanizing or RTV silicone) directly onto a component. The parts are then assembled, and the liquid cures to form a perfect, custom-fit seal. This process eliminates material waste, simplifies inventory, and creates a more reliable seal on complex, non-flat surfaces. It’s a perfect synergy of advanced chemistry and automated manufacturing, leading the way for the future of sealing technology.