The relentless pursuit of speed and precision defines modern manufacturing, robotics, and even digital fabrication. We see it in the blur of a robotic arm on an assembly line, the intricate dance of a 3D printer’s nozzle, or the pinpoint accuracy of a laser cutter. The ability to execute movements at incredibly high frequencies is a marvel of engineering. However, making a machine move fast is one challenge; ensuring it can do so with unerring accuracy, not just for a day or a week, but for millions of cycles over several years, is an entirely different and profoundly complex problem. This is the central struggle in regulating high-frequency movements: the battle against entropy and the slow, inevitable creep of error.

The Physical Toll of Repetition

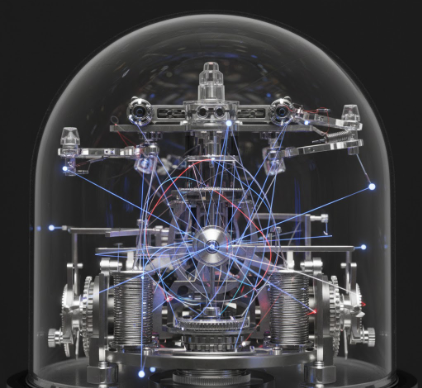

At its core, any machine that moves is a physical object subject to the laws of physics. When these movements are repeated thousands or millions of times per day, the accumulated stress is immense. The primary and most obvious challenge is

mechanical wear and tear. Every bearing, gear, belt, and actuator is in a constant state of friction and stress. Even the most robust materials will eventually degrade.

Think of a simple rotating shaft. At low speeds, the lubricant film remains stable, and the heat generated is manageable. But as you ramp up the frequency, the dynamics change completely. The lubricant can be flung off or break down due to increased heat. The bearings experience significantly higher cyclical loads, accelerating material fatigue. Microscopic imperfections in the metal can propagate into stress fractures. What begins as a deviation measured in nanometers can, after a few million cycles, become a micron, and eventually, a visible, tangible error that ruins a product or causes a system failure.

Heat: The Silent Enemy of Precision

High-frequency motion generates significant heat through friction and electrical resistance in motors. This heat is not just a waste product; it’s an active saboteur of accuracy. The phenomenon of

thermal expansion is a critical hurdle. As components heat up, they expand. A steel guide rail might grow longer by a few micrometers for every degree Celsius increase. While this seems insignificant, in a system calibrated for sub-micron accuracy, it’s a catastrophic deviation. The machine’s own operation actively works to de-calibrate it. This forces engineers to design elaborate cooling systems or, more cleverly, to build systems from materials with very low coefficients of thermal expansion, such as Invar or specialized ceramics, which are often costly and difficult to work with.

In high-frequency systems, errors rarely compound in a linear fashion; they often grow exponentially. A micron-level deviation in a drive component can cascade through the mechanical linkage, resulting in much larger inaccuracies at the tool tip. Overlooking small, seemingly insignificant inconsistencies during initial setup is a direct path to systemic failure over long operational periods. This is because tiny initial errors can excite resonant frequencies in the structure, amplifying the problem dramatically.

The Brains of the Operation: Control Systems and Feedback

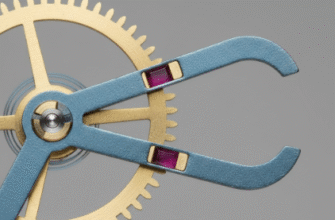

Modern precision machinery relies on sophisticated control systems to manage its movements. These systems operate on a simple but powerful principle: the feedback loop. A sensor measures the current position of a component, the controller compares this to the desired position, and an actuator is instructed to make a correction. It’s a continuous conversation between “Where are you?” and “Here is where you need to be.”

At low speeds, this conversation is easy. There’s plenty of time for the sensor to report, the controller to calculate, and the motor to react. At high frequencies, this loop becomes a frantic, high-speed chase. The primary challenge here is

latency. There is a tiny, unavoidable delay between the moment a sensor takes a measurement and the moment the motor responds to the corrective command. At thousands of cycles per second, this minuscule delay means the system is always correcting for a position that has already passed. This can lead to overshooting the target, creating oscillations, or inducing vibrations that further degrade accuracy.

The Ghost in the Code

While we often focus on the physical hardware, the software and algorithms driving the machine are just as critical and present their own unique challenges. The predictive algorithms that tell a robotic arm how to move from point A to point B are based on a perfect digital model of the machine. But the real machine is not perfect. It has worn bearings, slight misalignments, and is subject to thermal expansion.

This discrepancy leads to what is known as

algorithmic drift. The control software, working with its idealized model, issues commands that are no longer perfectly suited to the aging physical hardware. The feedback loop tries to correct for this, but it’s constantly fighting a system whose real-world parameters are slowly changing. Furthermore, the immense number of calculations performed every second can lead to the accumulation of rounding errors. A floating-point calculation that is off by a millionth of a decimal point is irrelevant once, but after a billion iterations, it can contribute to a measurable positional error.

Strategies for Long-Term Stability

Solving the challenge of long-term, high-frequency accuracy requires a multi-pronged approach that addresses both the physical and digital realms.

- Advanced Materials: The first line of defense is building machines from better materials. This includes using ceramics for their thermal stability and hardness, air bearings to eliminate mechanical friction almost entirely, and advanced alloys that are more resistant to fatigue.

- Smarter Sensing and Control: Instead of just measuring the position of the motor, advanced systems use multiple sensors, such as laser interferometers or high-speed vision systems, to measure the position of the actual tool tip. This allows the control system to compensate not just for motor error, but for flex and vibration in the entire machine structure. Adaptive control algorithms can also “learn” the changing characteristics of the machine over time and adjust their models accordingly.

- Predictive Maintenance: The rise of IoT and machine learning has enabled a new paradigm. By embedding vibration, temperature, and acoustic sensors throughout a machine, it’s possible to monitor its health in real-time. AI algorithms can analyze this data to detect the subtle signs of wear on a component long before it begins to impact accuracy. The system can then alert operators that a specific bearing is nearing the end of its life, allowing for replacement with minimal downtime.

Ultimately, achieving consistent accuracy in high-frequency systems is a dynamic and ongoing battle. It’s not a matter of building a perfect machine and turning it on, but rather of creating an intelligent system that can monitor itself, adapt to the inevitable degradation of its physical components, and compensate for the chaotic influence of its environment. The future of precision engineering lies not just in better steel and faster processors, but in creating machines that are, in a sense, aware of their own imperfections.