The hypnotic gleam of a perfectly polished watch case is no accident. It is the culmination of a painstaking, multi-stage process that transforms a utilitarian object into a piece of wearable art. While many watches leave the factory with a respectable shine, the pursuit of a true, distortion-free mirror finish—often called black polishing—is a discipline of its own. This level of perfection requires not just the right tools, but an immense reserve of patience and a deep understanding of the materials at hand. It’s a journey from a scratched or dull surface to one so flawless that it can appear black from certain angles, reflecting light with perfect clarity.

The Philosophy of the Flawless Surface

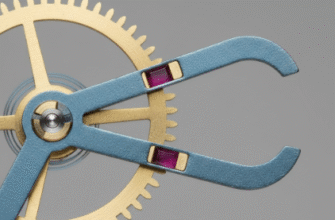

Achieving a mirror polish is less about making something shiny and more about making it perfectly flat. Any microscopic wave, dip, or remnant of a scratch will distort the reflection of light, preventing that deep, liquid-like appearance. The goal is to create a plane so uniform that light rays bounce off it in a perfectly parallel fashion. This is the secret behind the famed Japanese

Zaratsu polishing, a technique that relies on applying the metal to a rotating lap with incredible precision. The artisan doesn’t just buff the surface; they meticulously create geometrically perfect planes that meet at razor-sharp intersection points. This philosophy is key: you are not buffing out scratches, you are refining a surface to a state of near-perfect flatness.

Embarking on this journey requires a dedicated set of tools. While high-end equipment helps, the principles can be applied with a more modest setup, provided the technique is sound. The core arsenal for a watch polisher is surprisingly traditional, relying more on skill than on complex machinery.

The Foundation: Lapping and Sanding

Before any polishing compound touches the metal, the foundation must be laid. This is done through a process called lapping. You’ll need:

- A Perfectly Flat Surface: This is non-negotiable. A thick piece of float glass or, ideally, a small granite surface plate serves as the base.

- Wet/Dry Abrasive Papers: A full progression of grits is essential. This typically starts around 400 grit to remove deep scratches and progresses methodically through 600, 800, 1200, 2000, and even up to 5000 grit for a pre-polish finish.

The Heart of the Operation: Polishing Motor and Compounds

Once the surface is perfectly flat and prepped, the actual polishing begins. This stage brings out the shine.

- Polishing Motor: A variable-speed bench motor is ideal. The ability to control the RPM is crucial, as different compounds and wheels work best at different speeds.

- Polishing Mops (Wheels): You’ll need a variety. Hard felt wheels are used for initial cutting stages with more aggressive compounds. Stitched cotton and loose-leaf cotton mops are used for subsequent, finer stages of polishing and final buffing.

- Polishing Compounds: These come in bars or pastes, graded by abrasiveness. A common progression might involve a grey cutting compound (like Dialux Grey), followed by a green final-finish compound (Dialux Green), and perhaps an even finer rouge for the ultimate gloss.

Safety is paramount. Always wear safety goggles to protect your eyes from debris and compound flecks. A respirator or dust mask is essential to avoid inhaling fine metal and compound particles, which can be harmful. The spinning mop can easily grab loose clothing or jewelry, so work with care and undivided attention.

The Meticulous Step-by-Step Polishing Process

With the workshop prepared, the real work begins. Rushing any of these steps will compromise the final result. Each stage builds upon the last, and any shortcuts will be glaringly obvious in the end product.

Step 1: Complete Disassembly and Preparation

The watch case must be completely stripped down. The movement, crystal, crown, pushers, and case back gaskets must be removed. Attempting to polish an assembled case is a recipe for disaster, as compound will become lodged in crevices and you risk damaging sensitive components. Once disassembled, thoroughly clean all parts with isopropyl alcohol to remove any oils or grime.

Step 2: The Art of Lapping

This is arguably the most critical and challenging phase. Secure the first sheet of abrasive paper (e.g., 400 grit) to your flat lapping surface, using a little water to help it adhere. Place the watch case surface you’re working on flat against the paper. Using firm, even pressure, move the case in a figure-eight pattern. This motion helps to ensure you are removing material evenly and not creating a curved surface. The goal here is to remove all the original scratches and establish a single, uniform grain. Once you have a consistent finish, clean the piece thoroughly and move up to the next grit (e.g., 600). Repeat the process, but this time, orient your figure-eight pattern 90 degrees to the previous one. This helps you see when you have fully removed the scratches from the prior, coarser grit. Continue this progression all the way up to your finest paper. Do not skip grits. The time spent here determines the quality of the final polish.

The sharp intersection of lines, known as chamfers or bevels, must be preserved at all costs.

Step 3: The Initial Cut and Polish

Now, move to the polishing motor. Mount a hard felt or a stitched cotton wheel. With the motor running at a medium speed, lightly touch your cutting compound bar to the wheel to “charge” it. You only need a small amount. Bring the lapped surface of the watch case to the lower quadrant of the spinning wheel. Use

light pressure. Let the compound and the speed of the wheel do the work. Keep the piece constantly moving to avoid building up too much heat, which can discolor the steel, and to prevent “digging in” and creating a wavy surface. This stage will remove the fine sanding marks and begin to develop a bright, but still hazy, shine.

A key professional technique is to thoroughly clean the workpiece between each stage of polishing compound. Any residue from a coarser compound will contaminate the finer-grade mop, embedding larger abrasive particles that will prevent you from achieving a flawless final finish. Use a clean microfiber cloth and isopropyl alcohol for this crucial cleaning step.

Step 4: The Final Polish and High Gloss

Switch to a new, clean, loose-leaf cotton mop. Charge it with your fine finishing compound (e.g., green rouge). This stage requires an even lighter touch and often a slightly higher speed. Your goal is no longer to remove material, but to refine the surface you’ve already created. The haze from the previous step will melt away, revealing a deep, clear reflection. Move the piece gracefully across the wheel, polishing from different angles to catch every part of the surface. This step is what separates a good polish from a great one. The final result should be a dark, sharp, and undistorted reflection. You should be able to read text in the reflection from a distance without any waviness. That is the true test of a mirror finish.