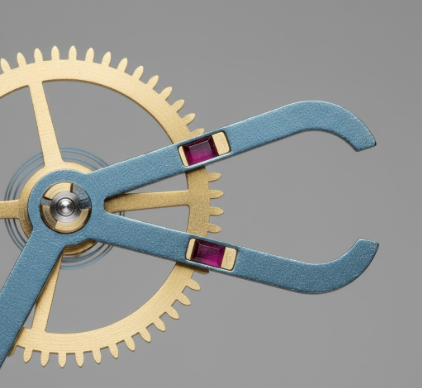

At the very core of every mechanical timepiece, hidden from view but audible with every passing second, lies a mechanism of extraordinary ingenuity: the escapement. It is the literal heartbeat of the watch, the component responsible for converting the steady, stored energy of the mainspring into the precise, metered oscillations that we perceive as time. While the balance wheel is often cited as the timekeeping organ, it is the intricate dance between the

escapement wheel and the

pallet fork assembly that enables this process. Understanding this interaction is to understand the very soul of mechanical horology.

Imagine the mainspring as a large reservoir of power, constantly trying to unwind and release its energy all at once through a series of gears known as the gear train. If left unchecked, this train would spin wildly and uncontrollably, exhausting the watch’s power reserve in mere moments. The escapement’s primary role is to prevent this, to ‘let escape’ this power in tiny, discrete, and perfectly timed increments. The two main actors in this drama are the escapement wheel and the pallet fork.

The Key Players on a Microscopic Stage

Before diving into their complex interaction, it’s essential to visualize the components themselves. They are marvels of micro-engineering, where tolerances are measured in microns and the geometry of every surface is critical to performance.

The Escapement Wheel: A Toothed Messenger of Power

The escapement wheel, at a glance, looks like another gear in the watch’s movement. However, a closer look reveals its unique and unusual nature. Instead of the simple, uniform teeth found on other gears designed for efficient power transmission, the teeth of an escapement wheel are distinctively shaped, often with elongated, pointed, or club-footed profiles. In the most common design, the Swiss lever escapement, these teeth are angled and polished to an incredible finish. This wheel is the final component in the main gear train, receiving the full torque from the mainspring. It is perpetually poised to spin, held back only by its partner in time, the pallet fork.

The Pallet Fork Assembly: The Master Conductor

The pallet fork is a small, lightweight lever, typically shaped like an anchor or a ‘T’. It pivots at its center. At one end is the ‘fork’ itself, a C-shaped slot that interacts with a jewel on the balance wheel. At the other end are two arms, each holding a tiny, meticulously shaped synthetic gemstone, usually a ruby. These are the

pallets, specifically the ‘entry pallet’ and the ‘exit pallet’. The shape, angle, and polished surfaces of these pallet jewels are of paramount importance. This entire assembly acts as the crucial intermediary, linking the raw power of the escapement wheel to the precise, oscillating rhythm of the balance wheel.

The primary function of the escapement is twofold. First, it locks and unlocks the gear train, allowing it to advance in discrete steps. Second, and just as importantly, it delivers a tiny impulse of energy to the balance wheel on each swing. This impulse is vital to counteract the effects of friction and keep the balance wheel oscillating at a constant frequency.

The Intricate Dance: A Step-by-Step Breakdown

The interaction between the escapement wheel and the pallet fork is a rapid, continuous cycle that occurs multiple times per second. Let’s slow it down to understand the precise sequence of events that produces the familiar ‘tick-tock’ sound.

1. The Locked State: We begin with the watch in a state of momentary rest between ticks. A tooth of the escapement wheel is pressed firmly against the locking face of one of the pallet jewels, let’s say the entry pallet. This single point of contact holds the entire gear train, and thus the mainspring’s power, in check. The pallet fork is held stationary in this position.

2. The Unlock: The balance wheel, the true timekeeper, is swinging back towards its central position after completing a swing. Mounted on its staff is a small jewel pin, the impulse jewel. As the balance wheel swings through its arc, this impulse jewel enters the slot of the stationary pallet fork and gives it a small nudge. This nudge is just enough to move the lever, causing the entry pallet to slide away from the escapement wheel tooth it was holding.

3. The Impulse and Drop: The moment the tooth is unlocked, the power from the mainspring causes the escapement wheel to begin turning. As it turns, the specially shaped tip of the tooth slides along the angled ‘impulse face’ of the pallet jewel. This sliding action gives a tiny, precise push to the pallet jewel, which in turn pushes the fork. This push is the ‘impulse’ – the critical transfer of energy that is transmitted back through the fork to the balance wheel’s impulse jewel, giving it the kick it needs to continue its next oscillation. This action is the ‘tick’. Immediately after delivering this impulse, the escapement wheel tooth ‘drops’ off the end of the entry pallet jewel.

4. The Opposite Lock: The escapement wheel only turns a very small amount before another tooth, several positions down the wheel, makes contact with the locking face of the

exit pallet, which has swung into the wheel’s path. The gear train is once again locked, and the entire system is momentarily at rest. This locking action produces the ‘tock’ sound. The balance wheel, meanwhile, is now free to complete its swing on the other side, unimpeded.

5. The Return Journey: After reaching the peak of its swing, the balance wheel reverses direction, driven by the hairspring. Its impulse jewel once again enters the pallet fork slot, this time from the opposite direction. It nudges the fork back, unlocking the escapement wheel tooth from the exit pallet. An impulse is delivered from that tooth to the exit pallet, the wheel drops, and is subsequently locked again by the entry pallet. The cycle is complete and repeats itself, thousands of times per hour, with unwavering consistency.

The escapement is an incredibly delicate and high-friction system. Its precision depends on perfect geometry, flawless surface finishes, and microscopic amounts of specialized lubricants. Over time, these lubricants can dry up or become contaminated, drastically affecting the watch’s accuracy. This is why regular servicing of a mechanical watch is not just recommended, but absolutely essential for its longevity and performance.

This beautifully choreographed sequence is the essence of mechanical timekeeping. The escapement wheel provides the power, but it’s the pallet fork, governed by the balance wheel, that dictates the rhythm. It is a system that brilliantly solves the problem of dividing a continuous flow of energy into discrete, measurable units of time, creating a symphony of motion from just a few ingeniously designed components.